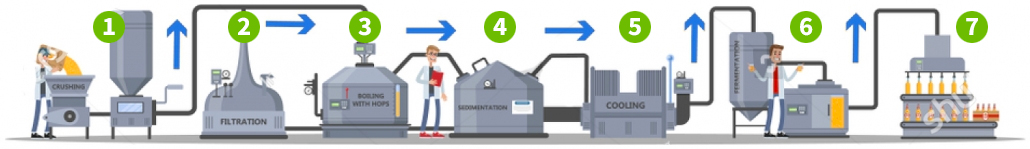

Brewing

Optimising plant processes

Optimising plant processes ranging from malting to kegging to packaging to maximise production volumes through bespoke control systems.

1 – Milling | 2 – Mashing | 3 – Lautering | 4 – Brewing | 5 – Cooling | 6 – Fermenting | 7 – Packaging

We do this by putting controls in place to ensure:

The concept of the digital twin was introduced over two decades ago. Today’s technology now makes it possible to feed operational data back into the complete value chain, creating the opportunity to continuously optimize both product design and production activities in a closed-loop decision-making process.

- temperatures are optimised and stable,– volumes added, moved and stored are correct,

- pressures are maintained to maximise plant capabilities,

- filling lines are running and fully utilised,

- packaging is automated and cost-effective,

- production is cleaned through effective CIP controls,

- Operators are safe through controlled safety interlock

Currently working with